About Company

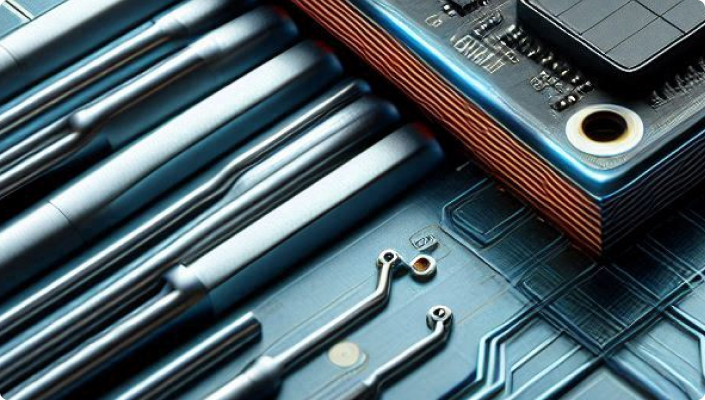

Founded in 1992, Interm was established by a group of scientists and engineers who had been performing fundamental and applied research in the field of thermoelectricity for many years and combined their knowledge and expertise to develop innovative technologies of thermoelectric module assembling and implement them in full-scale manufacturing.